Coal Forge Plans

What is the most economical forge that a person can make?

This question

comes up in my classes occasionally. This page will give you some options to create

a forge for as little money as possible. Please understand that you will probably

be able to do more work with greater comfort and efficiency if you spend a little

more money.

The cheapest type of forge is a coal forge. All a forge is, is

a container to hold the coals and an air source that can be controlled. The simplest

form would be a shallow square hole in the ground about 6 inches deep and 10 inches

on a side, with a pipe running under ground, into the side of the hole, about 2 inches

above the bottom. You then need a bellows or blower to push air into the pipe and

into the coals. This side draft forge works best for charcoal. It has limited use

since the bottom 2 inches needs to be cleaned out of ash periodically. This type

of forge means that your anvil should be on the ground near the forge, and you will

probably be working on your knees. For the ultimate in economy a rock could be used

for an anvil. Obviously this is the least desirable forge but it will work.

It

is worth spending the time at a scrap yard to find a chunk of steel that has a couple

of flat surfaces that can be used as an anvil.

The first forge I had was a

combination of a Habachi and a hair dryer. Again economical but not the best solution.

So

how do you make a decent forge with common items for a minimal cost?

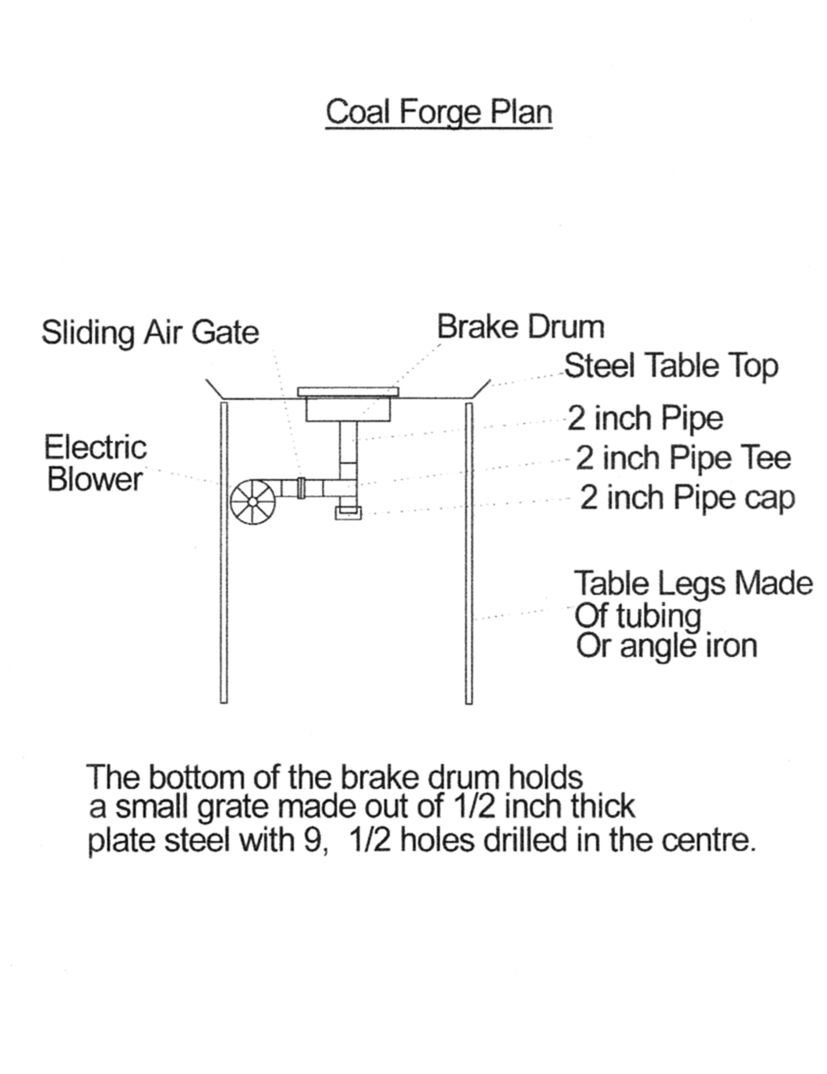

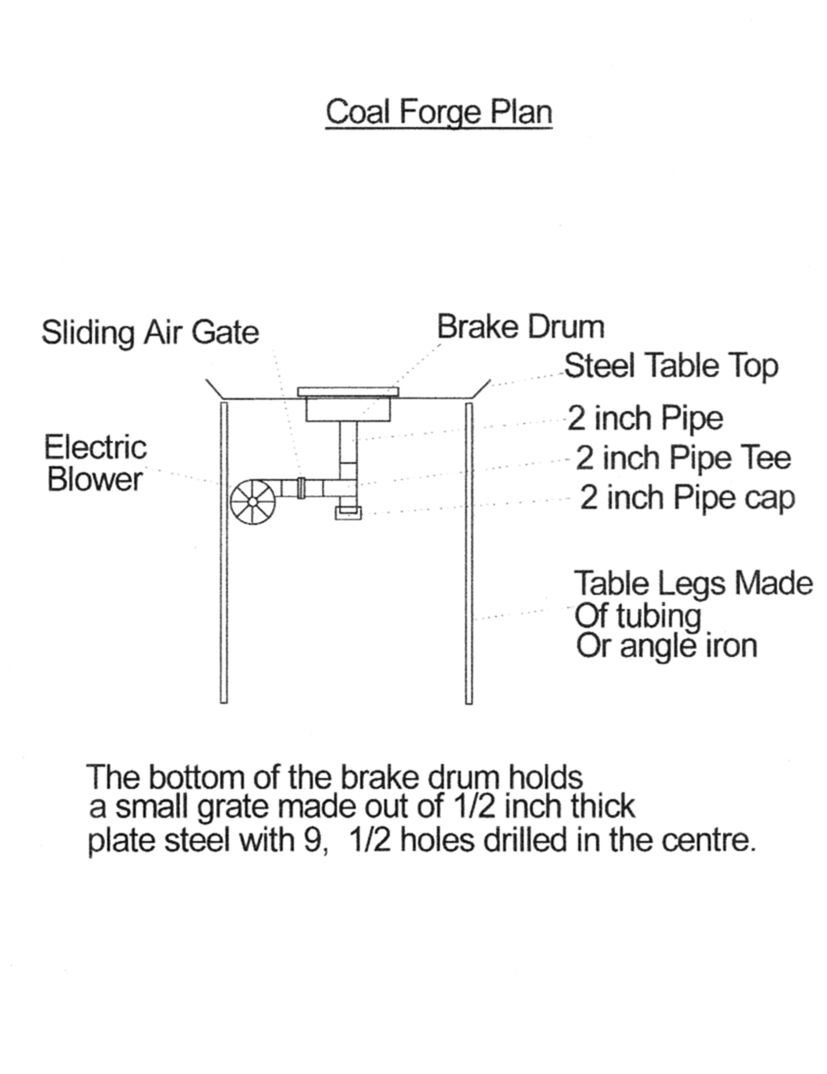

Method

1)

You will need:

Small Brake Drum

Steel Barrel

2 inch pipe

2 inch

pipe Tee

2 inch pipe cap

2 inch short pipe nipple

Dimmer switch

Light

switch

Electric blower

Electric cord and plug

1/2 in thick plate with 9,

1/2 inch holes in it. This plate must fit in the bottom of the brake drum with the

9 holes over the centre of the 2 inch pipe.

The best electric blower is one

from a gas furnace or gas water heater. New they cost about $110.00. You may be able

to find one used. A high velocity hair dryer will work, but don't expect it to last

for ever, but they are easy to find at yard sales or junk shops. Another possibility

for a blower is an old vacuum cleaner with an exhaust connection. The blower can

be controlled with an off on light switch or a dimmer switch. Neither are the best

solution. The dimmer switch can control the speed but becomes burned in the favorite

spot, and then you have to switch the position. The on off switch gives you full

blast then zero so you must be completely attentive to the temperature of the steel,

or you can easily burn it.

The best solution is a sliding gate valve. This

needs to be constructed so that a piece of sheet steel slides across the air flow

to block it all off. A handle is attached to control the amount air from zero to

maximum.

A steel barrel can provide both the stand for the forge and the steel

table top to hold the brake drum fire box, and the coal. You will need to cut a hole

in the top that a small brake drum from a small car will slide into but not fall

through ( there is a lip on the brake drum). You will also need to cut a hole in

the side that to allow the 2 inch air pipe to go through. A third hole large enough

to empty the ash trap in the bottom of the air tee will be required.

Method 2)

Uses the above components but instead of the barrel a steel table

is fabricated using sheet steel and tubular or angle iron legs (see the diagram)

the sliding air valve is better than the dimmer switch but a little more difficult

to construct.

The

2 inch pipe needs to be welded to the bottom of the brake drum but the other pipe

components can be threaded together. The table and legs should be welded together

for strength with lower leg braces. These could also be bolted together. 3 legs are

more stable then 4, but it is easier to put wheels on 2 legs of the 4 legs. Some

people have been successful in using a scrapped barbecue as a forge base.

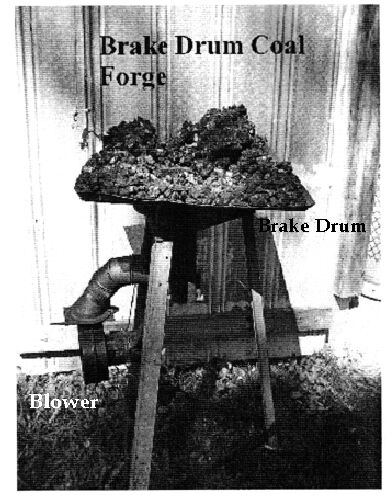

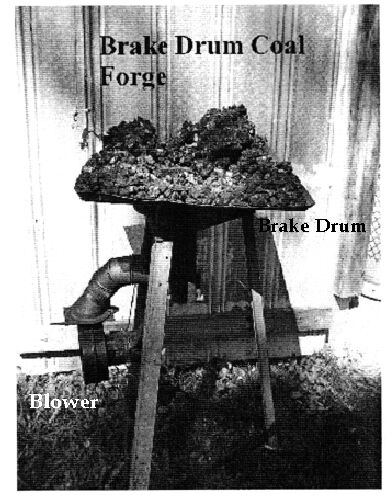

This image shows how I constructed a small coal forge using scrap material. This

one has 3 legs. Another design for a first coal forge can be found at www.anvilfire.com/forges.

Spend the time and look around this site as there is a great deal of info here. The

FAQ section of www.anvilfire.com is very useful for

beginers. Read all and most of your questions will be answered.