A Silly Little Forge Burner

You Use This Information Completly At Your Own Risk

I recently decided to make a small burner for a small forge. This burner is

easily made with a minamum of tools. It is suitable for a small chamber size of

80 to 100 cubic inches.

And should run at a pressure of 15 psi or higher. At

15 psi the output is 12000 btus. In a small chamber it will take a 3/8 square bar

up to a reasonable yellow temperature.

The 3 inch nipple has a thin piece of steel welded on the end to cap it. The

overhang is then ground smooth to match the line of the pipe, and the end is ground

perpendicular. I drill 1/64 hole in the centre of the end as the gas oriface. The

1/8 pipe fits with only a little slop and is secured in place with a 1/4 inch set

screw. I have drilled 12, 1/4 inch holes just past the set screw. The other end

is threaded and a standard 3/8 coupling is threaded on. Attached to the other end

of the pipe nipple is 1/8 street elbow and a valve. I would recommend a ball valve,

but in this photo I have used a needle valve.

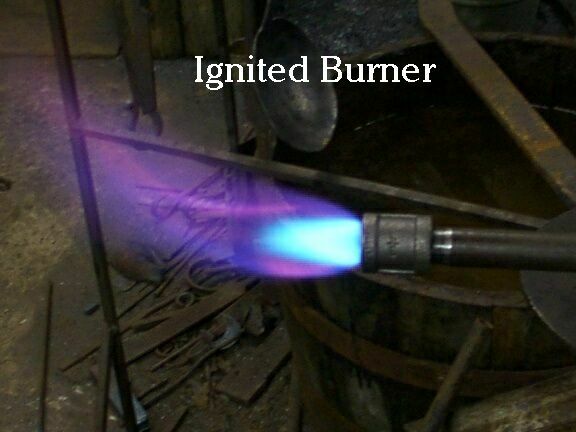

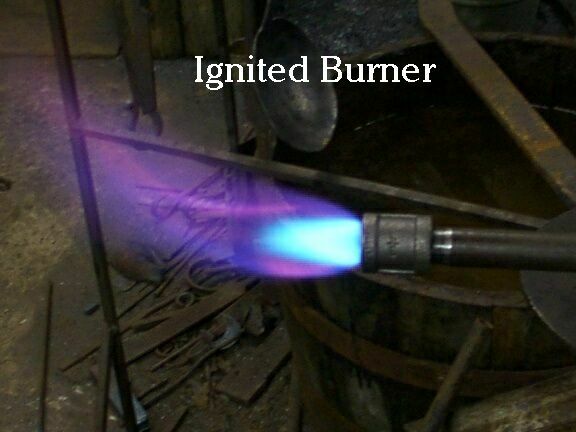

The next image shows the burner running at 15 psi.

I have also had success with a modification of this burner for glass bead making.

This is not a hot torch so the glass melts slowly but it supplies enough oxygen

to keep the glass from getting smoky. If you have questions about this modification

please email me.